Description

Silver Electrolysis Refining Machine

Key attributes

| warranty | Not Available |

| key selling points | High-accuracy |

| Place of Origin | Guangdong, China |

| Warranty | 1 Year |

| video outgoing-inspection | Provided |

| machine type | gold recovery machine |

| core components | PLC,Pump,motor |

| brand name | XHF |

| Product Name | silver electrolytic refining machine |

| After-sales Service Provided | online service support |

| Function | Refining silver with a purity of 90% to 99.99% |

| Application | refining olfd silver jewelry and silver scrap |

| Capacity | 10kg/day |

| Voltage | 220V/380V |

| Power | 1kw |

| Material | PP+titanium |

| Feature | High purification efficiency |

Packaging Details Port of dispatch Selling Units Single package size Single gross weight Supply Ability

wooden box packing shenzhen Single item 73X58X103 cm 77.000 KG 600 sets per Year

Product descriptions from the supplier

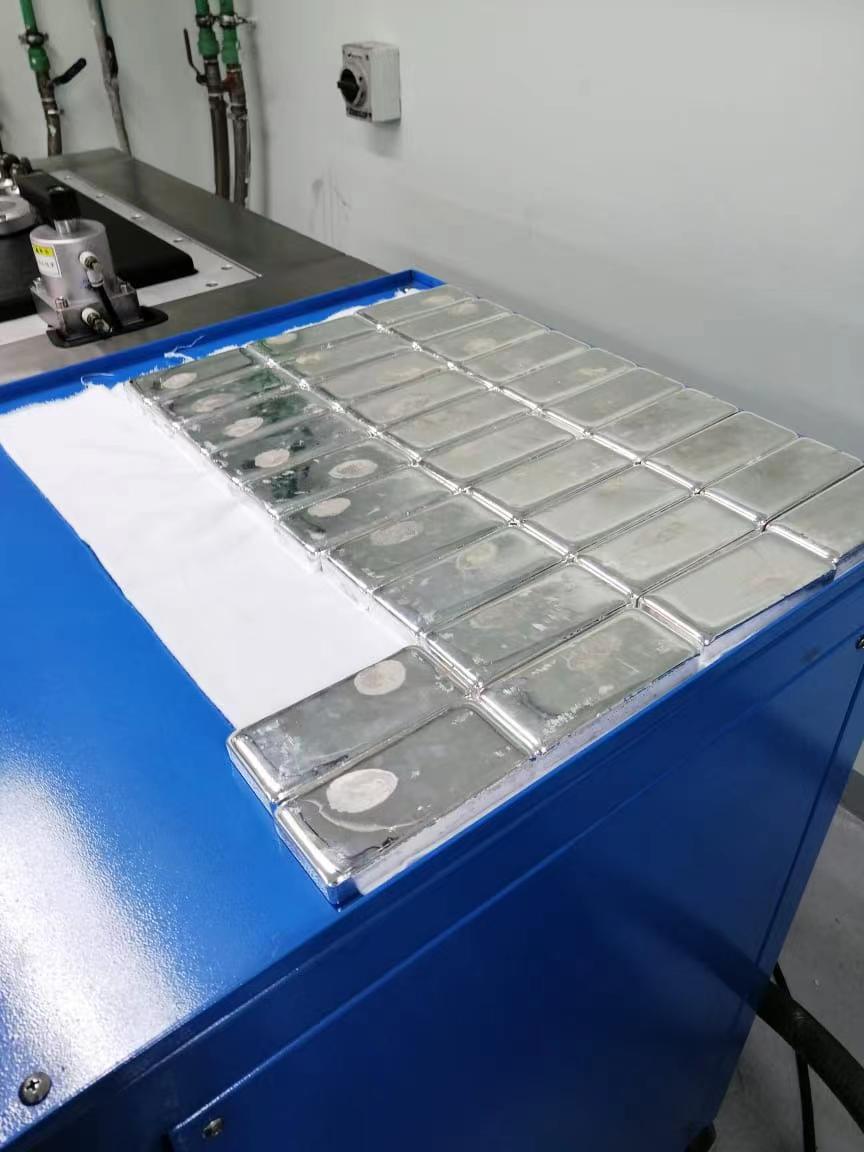

High Efficiency Silver Electrolytic Refining Machine From 90% silver to 99.9 % or 99.99% silver

Power:1KW or others

Capacity:10kg/day 50kg/day or customized

Function:Refining silver bars with a purity of more than 90% to 99.9 % or 99.99%. If the purity of the silver bar is not high, it needs to be refined several times.

Application: it is mainly used to refining old silver jewelry and silver scraps.

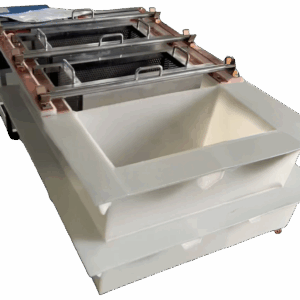

Working Principle: we put the old 925 silver jewelry into the four-round titanium baskets. and we add 10% nitric acid solution into the machine.

During the working of the machine, the silver will be dissolved in the dilute nitric acid solution, and then through electrolysis, the silver in the solution will be electrolytically reduced and adsorbed on the rotating cathode again. As a result, silver with a purity of 9999 is obtained.

Potion ratio: 10% dilute nitric acid.

The number of times to change the potion: it is based on the purity of the silver block content. For example, the silver potion with low silver content and high impurity content has a poor cleanliness, and the potion needs to be replaced once for each Refining. For example, if the silver content is high and the silver block with few impurities , the potion can be reused several times, and the number of changes depends on the cleanness of the potion.

Using Instructions:

1.Check whether each screw position of the equipment is tightened, whether the titanium basket bag is damaged, and the water inlet valve and the water outlet valve are closed.

2.Strictly proportion water and nitric acid 100: 10 , First prepare a potion with 10% dilute nitric acid.

3.Silver nuggets are evenly placed in 4 titanium baskets, and then poured into a 10% dilute nitric acid potion. The potion must be higher than the silver bar soaked surface.

4.Turn on the power switch. The adjustable voltage CV of the device is in the range of 5V-8V. The current is changed with the increase of the voltage and does not need to be adjusted. Click the electrolytic stirring switch device to operate normally.