Description

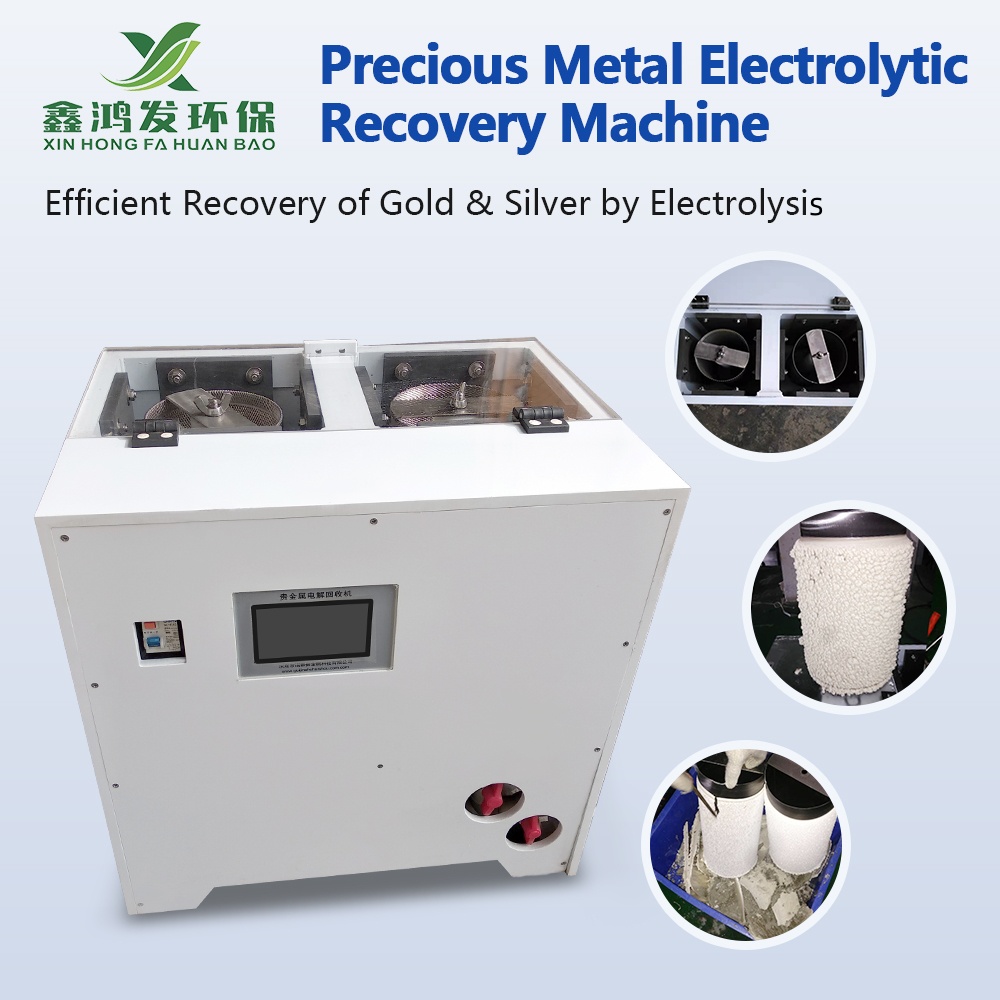

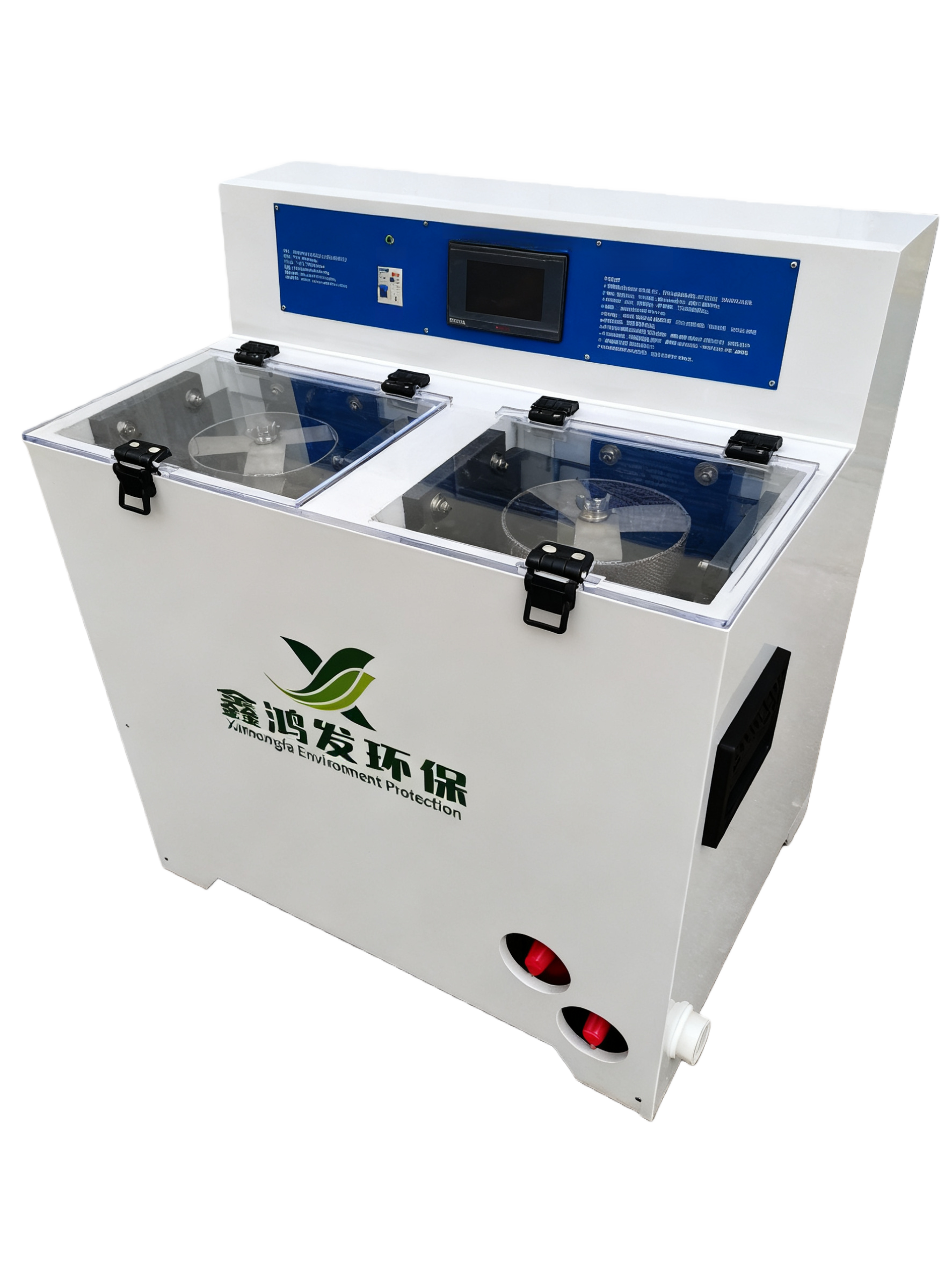

Precious Metal Electrolytic Recovery Machine

Electrolytic Recovery Machine of Precious Metals From Plating Solution and Electronic waste or jewelry deplating solution

High-frequency pulse electrolytic recovery machine of precious metals that independently developed and researched by our company can effectively restore silver (or gold or copper or nickel) ions directly to metal block with automatic intelligent control. The purity reaches to 99.8%.

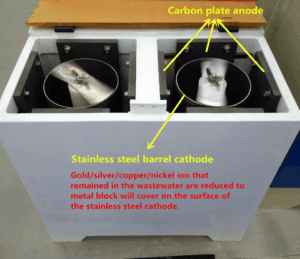

Recovering principle: The use of the principle of electrolytic adsorption to restore liquid metal ions to metal, and metal adsorbed on the cathode, peeling off the metal residue, re-refining and use.

Application: The machine focus on recovering gold , silver, platinum, rhodium in the plating solution,drag-out tank, strip solution, plating rinsewaters and Iodine and iodide etching solution. The machine also can recovery precious metal ( Au, Ag) from e-waste stripping solution,waste photography developing solution, electronic plating waste solution and gold/silver mine operations.

Key Benefits and Features:

- A cost-effective solution capable of lifting heavy industrial loads or materials

- Controllable Speed with remote operation options for enhanced safety

- Comes with compact and energy-efficient European-style electric wire rope hoist

- Equipped with remote control options for enhanced safety during operation

- Boasts bridge crane features for guaranteed operational stability

- Impressive span length of up to 49 meters for enhanced load-handling

- Customizable to fit your industrial needs

- Comes with the necessary support services you may need

Specifications:

| Descriptions | Details |

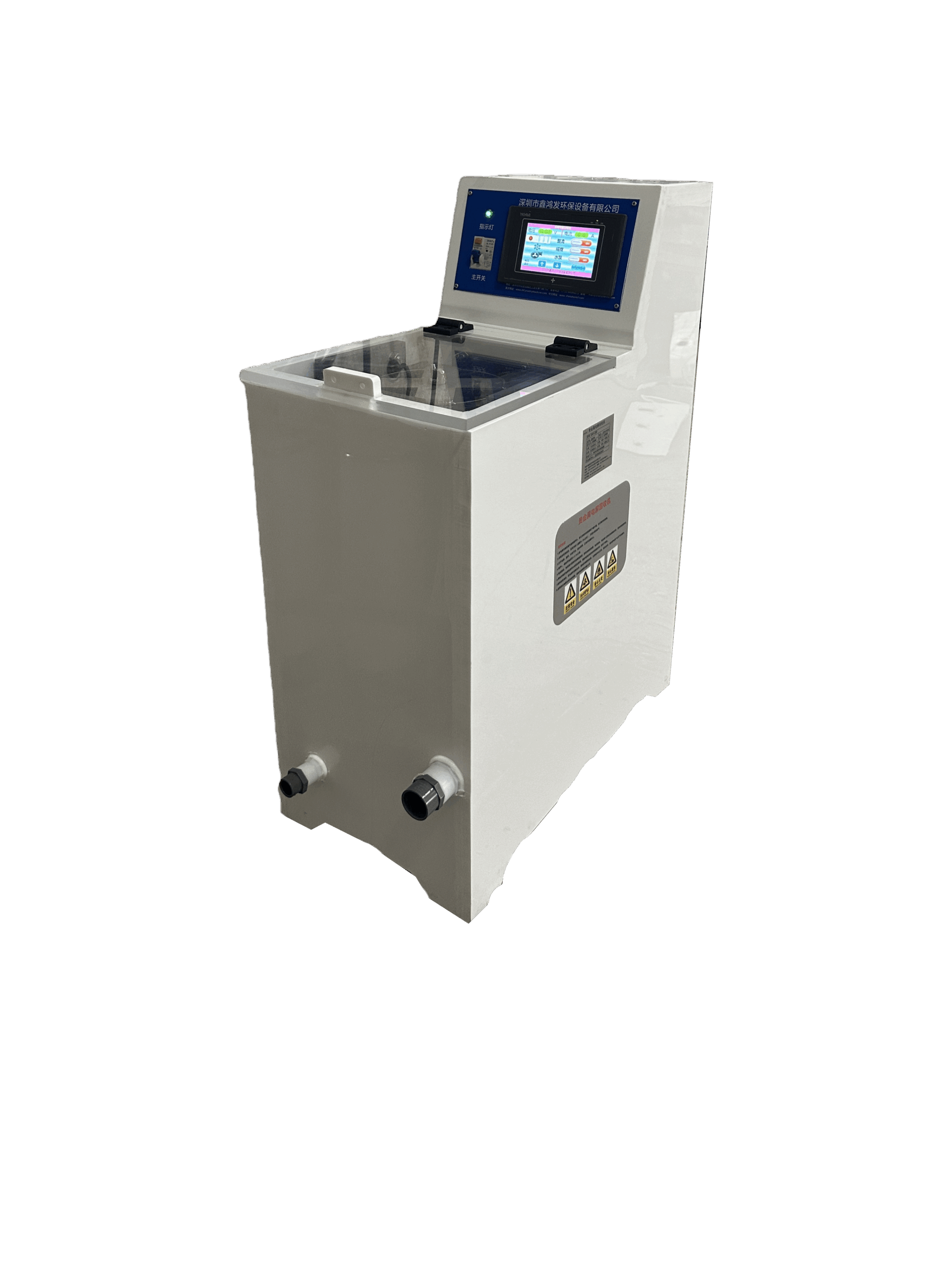

| Key Components | PLC, motor, Pump |

| Origin | Guangdong, China |

| Warranty Period | 1 Year |

| Tare Weight | 50 kg |

| Machinery Test Report | Not Available |

| Brand Name | XHF |

| After-sales Service Provided | No overseas service provided |

| Product Name | Electrolytic Gold Recovery Equipment |

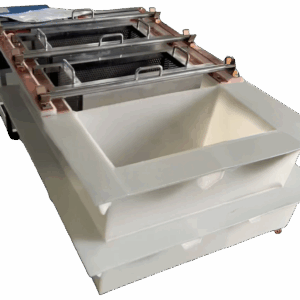

| Shell Material | PP |

| Voltage | 220V/380V |

| Power | 300W 350W 400W 500W |

| Function | Recovering precious metal in the plating solution |

| Recovery Rate | ≥99% for gold & silver,≥90% for cooper & nickel

&Platinum & Palladium |

| Feature | Easy to install, small space required, high efficiency |

| Trade Terms | EXW,FOB,FCA,CFR,CIF,DDP.etc |

| Delivery time | 7-15 days |

Product descriptions from the supplier

Video Description

Recovering principle: The use of the principle of electrolytic adsorption to restore liquid metal ions to metal, and metal adsorbed on the cathode, peeling off the metal residue, re-refining and use.

Applications

This machine is designed for efficient recovery of precious metals from a variety of industrial solutions and rinsewaters. It is widely used in electroplating, electronics, and refining industries. Typical applications include:

-

Recovery of gold, silver, rhodium, platinum, and palladium from plating solutions.

-

Recovery of gold, silver, rhodium, platinum, and palladium from drag-out tanks.

-

Recovery of gold, silver, rhodium, platinum, and palladium from plating rinse waters.

-

Recovery of gold and silver from strip solutions.

-

Recovery of gold and silver from iodine and iodide etching solutions.

-

Recovery of silver from fixer solutions (commonly used in the photographic industry).

Recovery machine of gold, silver and other precious metals:

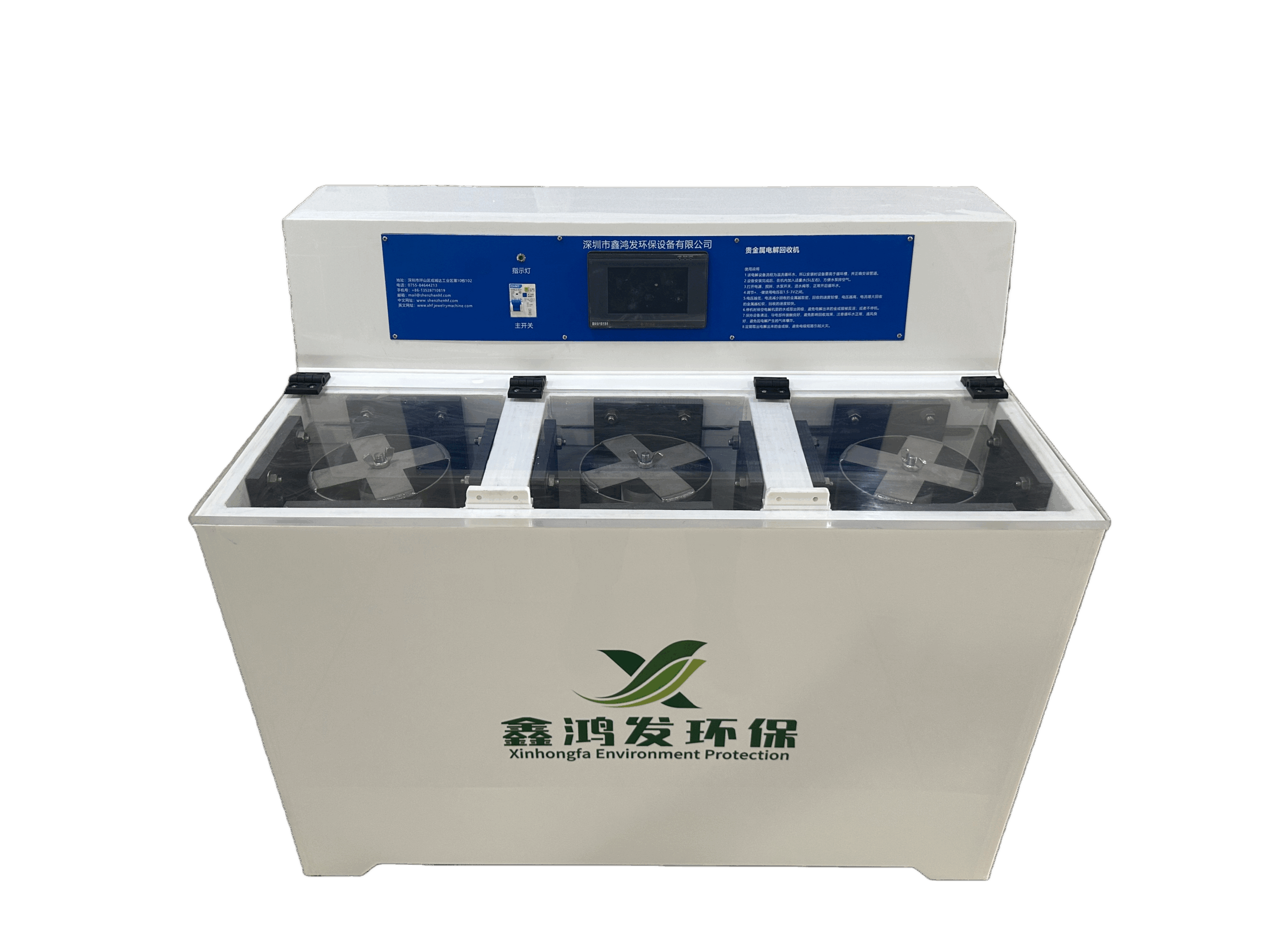

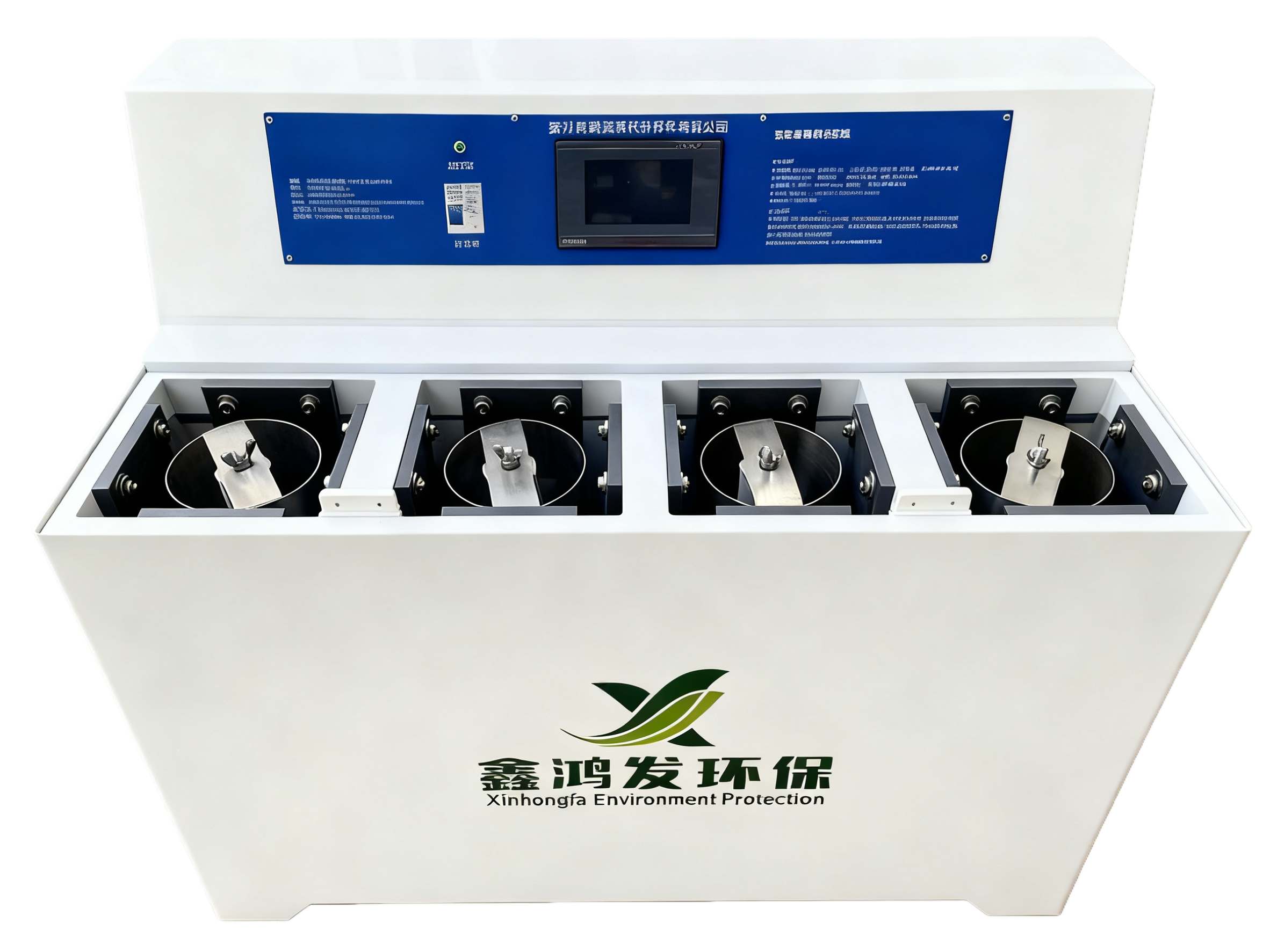

Model Specification Water Treatment Amount Voltage Power Silver Gold JY200 300*450*600mm 150-200L/day 100-150L/day 220V 300W JY400 600*450*600mm 300-500L/day 200-350L/day 220V 350W JY600 900*450*600mm 500-800L/day 300-500L/day 220V 400W JY800 1200*450*600mm 600-1000L/day 500-800L/day 220V 500W

Features of precious metals electrolytic recovery machine:

1. Simple: It is installed at the production line. Automatic electrolysis can be realized, transportation is not necessary.

2. High recovery rate: gold and silver ≥99%; copper and nickel ≥90%;

3. Convenient extraction: Recovered precious metals with high purity can directly cover the anode. Precious metal block can be taken away immediately after separation.

4. Operating costs low: the machine uses a rotating cathode, high frequency pulse intelligent electrolytic method to recover gold or other precious metal. Do not need to consume any consumables and electrolytic accelerator, only need to consume a small amount of electricity. Greatly reduce the operating costs.

5. The content of precious metals in waste liquid after recovery: silver be lower than 5-20ppm , gold be lower than 2-10ppm.