Description

| Voltage | Video Outgoing-inspection | Key Selling Points | Machine Type | Weight(KG) | Brand Name | Product Name | Size | Function | Warranty | Trade Terms | Core Components | Machinery Test Report | Power(W) | Place of Origin | Heating System | Power | MOQ | Payment Method | Selling Units |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

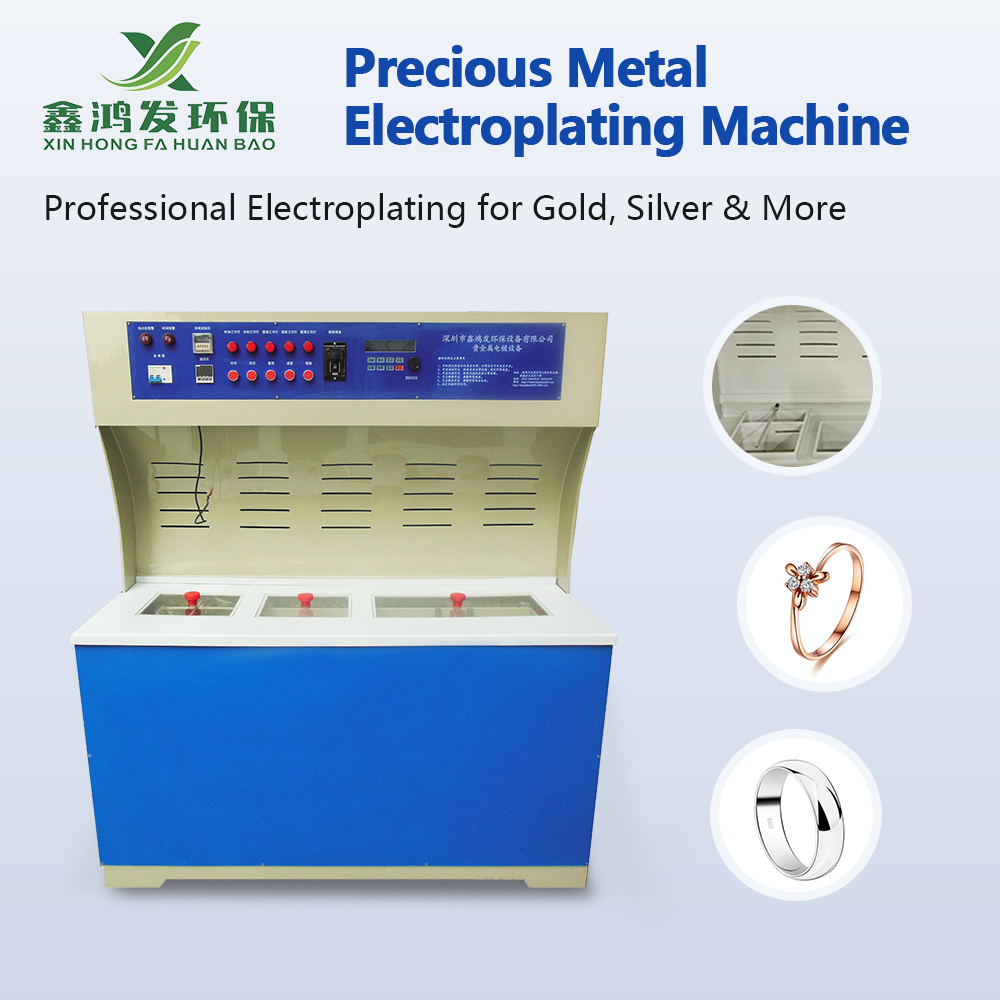

| 220V/380V | Provided | Easy to Operate | Precious Metal Jewelry Plating Machine | 200 | XHF | Custom Electroplating Equipment Production Machine | 1380*750*1650mm | Electroplating Jewelry | 1 Year | EXW,FCA,FOB,CFR,CIF,DDP,DDU.etc | Rectifier,Anode and Cathode | Not Available | 120W | Guangdong, China | 3KW | 12V/10A | 220V/380V | 1SET | Single Item |

Application:

It can use to plate all kinds of precious metal jewelry.(contains gold /platinum /silver /rhodium /palladium etc.)

Production material: industrial pp plate

Device configuration:

(1) 12V/10A rectifier

(2) platinum anode net

(3)low water level and alarm device

(4)heating and temperature control device

(5) time control and alarm device

(6)plating liquid circulation and filtration device

(7) right and left swing device and speed regulating device

(8) manual swing device

Advantages of precious metal plating machine

1.All functions in one machine: the machine including plating, recycling and cleaning the multi-function in one body.

2.Ensure good product quality: it was equipped with time automatic control device, and can control the plating time exactly, to ensure that the thickness and colors of the plating parts.

3.The operation is very standard: configuration is complete .and it was equipped with control buttons and adjust switch on the control panel, in addition we also indicate the operating rules. not only operation standard and easy to operate.

4.Durability: the machine made by stable performance and corrosion resistance of pp plate. so it has long service life.

5.Small footprint: the machine volume is small and exquisite, save floor space.

6.Improve the working environment: for solving the shortcomings of traditional direct plating that solution easily spills. in designing of device structure has made improvements to ensure that plating solution will not spill, on the other hand ,it comes with suction hood canefficient suck up the cyanide waste gas generated in the electroplating process. So that the work environment become better.

7.Precious metal recovery: it was equipped with a waste liquid recovery tank to reduce the loss of precious metal remaining in the plating solution.

Analysis the disadvantage of traditional precious metal plating

1. poor working environment: traditional metal plating method is directly operated by a beaker on plating, plating solution splashed around easily. as plating solution are poisonous, operator work in this bad environment for a long time, will cause damage to the body.

2. Waste of precious metals: it is difficult to recovery the precious metals in the plating solution after plating ,so it caused the waste of resources.

3. operation is not convenient: after the completion of electroplating, plating parts can not approached for cleaning.

Ordering instructions:

1.According to requirements of customers to customize the machine.

2.Our company also can provides design and manufacture of the entire production line of the plating line. According to requirements of customers to customize the plating line.

such as: Degreasing+Water rinse+Water rinse+Acid +DI rinse+DI rinse+Rhodium plating+Recovery+Gold plating+Recovery+Gold plating+Recovery+ATB616plus tank+DI rinse+Water rinse+\Water rinse+DI rinse+DI rinse(hot water).

Project case: