Description

| Voltage | Video Outgoing-inspection | Key Selling Points | Machine Type | Weight(KG) | Brand Name | Product Name | Filter System | Function | Warranty | Trade Terms | Core Components | Machinery Test Report | Power(W) | Place of Origin | Dimension(L*W*H) | Heating System | Power | Inner Size | MOQ | Payment Method | Selling Units | Single Package Size |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 200V/380V | Provided | Long Service Life | Nickel Sticker Electroforming Machine | 200 | XHF | Custom Electroforming Machine for Signs,Nameplating,UPs | RTG-1001,RTG-2001,RTG-1004 | Electroforming Nickle Sticker and Logo | 1 Year | EXW,FCA,FOB,CFR,CIF,DDP,DDU.etc | Pump,Rectifier,Anode and Cathode | Not Available | 1KW,2KW,3KW,4KW | Guangdong,China | 1630*1200*1400MM | 1KW,2KW,3KW,4KW | 30A/12V,50A/12V | 600*400mm | 1SET | L/C,T/T,Western Union,Paypal | Single Item | For Costomizing |

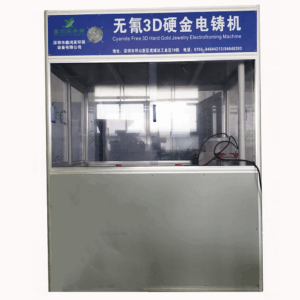

Electroforming Metal Sticker Machine Electroformed Nickel Sticker

Metal sticker electroforming machine can be used to electroforming the following products:

Signs, logo, stickers, etc. Gold electroforming, silver electroforming, or nickel electroforming are decided based on actual needs. Nickel electroforming is the most common. also include the following products.

Electroforming trade mark (thick) electroforming metal pads (thin) Nickel electroforming UP signs

The main system parameters of the machine(the actual ordering can be adjusted based on process)

| Model | Specification (inner diameter) |

Filter system | Electroforming power | Heating system | Anode |

| 100L | ø600*400MM | RTG-1001 | 30A/12V | 1KW | YD/PT |

| 120L | ø600*500MM | RTG-2001 | 50A/12V | 2KW | YD/PT |

| 150L | ø600*600MM | RTG-1004 | 50A/12V | 3KW | YD/PT |

| 180L | ø600*700MM | RTG-1004 | 50A/12V | 4KW | YD/PT |

Usage:

Signs,logo and stickers are applicable to a variety of household appliances, computer monitors, mouse, audio, furniture, security doors, glass products, plastic phone shells, mobile phone PU cases, stainless steel cups, belts mouth, mobile phones, motorcycles , gift boxes, pieces of iron, pianos, guitars, wine boxes and other crafts.

Production Process:

The whole process of nickel sticker electroforming

Stainless steel plate → grinding and degreasing → silk screen → exposure and development → master plate → electroforming nickel → electroplating chromium → peeling → gluing → sticking release paper → cutting → packaging and warehousing

Production process can be simply divided into the following steps:

1. Plate burning: stainless steel plate is used as electroforming mother set.

2. Electroforming: Treated stainless steel plate with images will be fixed with a specialized gripper, and put in nickel electroforming tank quickly.

3. Separation: Electroformed texts and pattern shall be separated completely with transfer membrane.

4. Sizing treatment: The first method is screen printing; the second one is to transfer adhesive to the paper and then print patterns and texts.