Description

Large-Scale Silver Stripping Machine

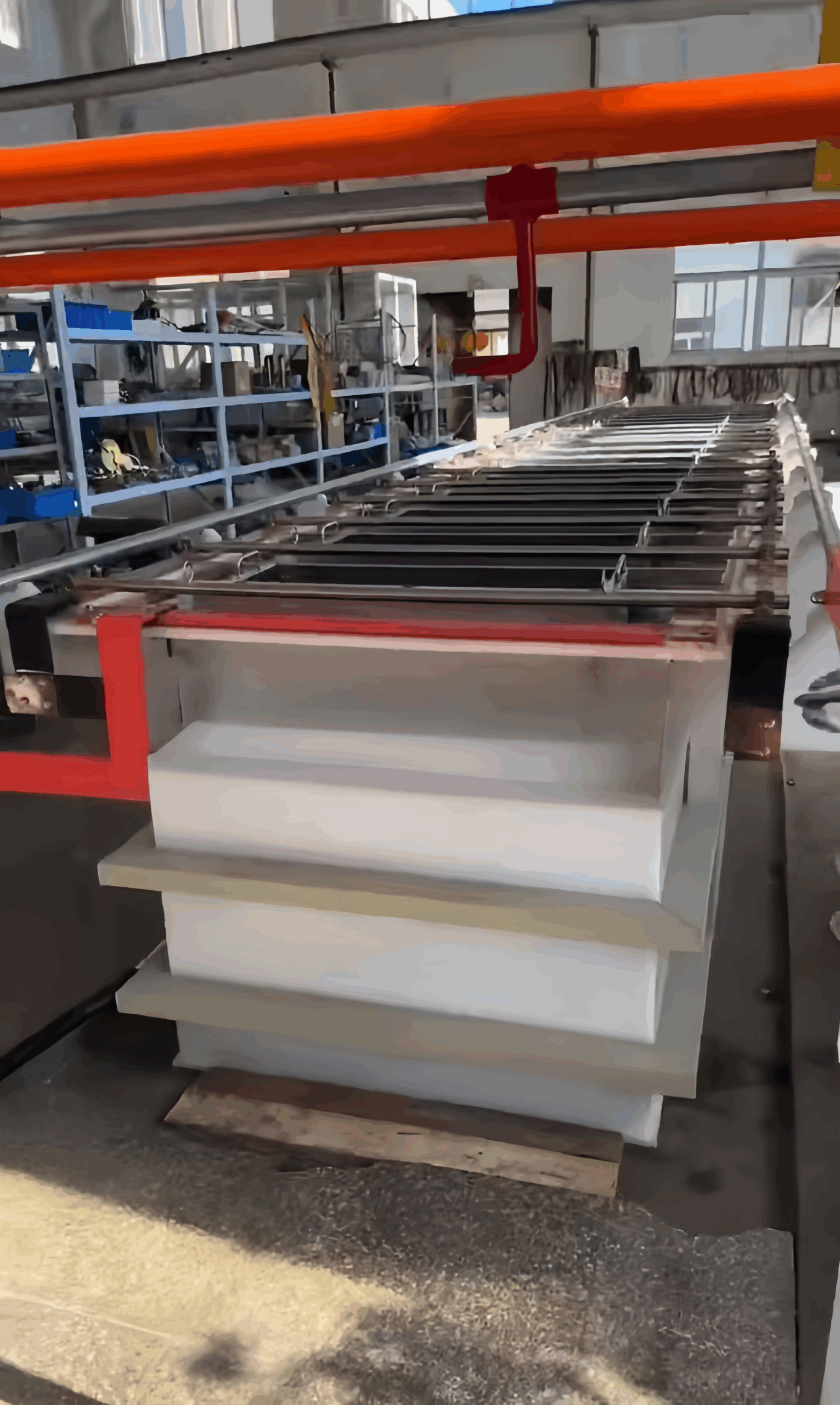

| Total Length of Equipment | Tank Material | Overhead Crane Material | Basket Material | Quantity | Basket Size | Tank Capacity | Voltage | Total Power |

|---|---|---|---|---|---|---|---|---|

| 5 × 1.6 × 3 m | PP (Polypropylene) | Iron | Stainless Steel | 6 units | 80 × 20 × 80 cm | 2000 L | 380 V | 10 kW |

The Large-Scale Silver Stripping Machine is an advanced industrial solution designed for the efficient removal and recovery of silver from various metal surfaces, plating baths, and industrial components. With its robust structure and professional engineering design, this machine is widely applied in the jewelry industry, electronics, metal finishing plants, and recycling facilities. It offers businesses a cost-effective, safe, and environmentally friendly method to handle silver stripping and recovery on a larger scale.Its versatility allows companies to integrate it into different production and recovery processes, ensuring maximum utilization and efficiency.

High Efficiency and Reliable Performance

The Large-Scale Silver Stripping Machine is engineered for high throughput and stable operation. It can process significant volumes of silver-coated materials in a single batch, dramatically reducing labor time compared to manual stripping methods. The use of advanced electrolytic technology ensures consistent stripping results, maintaining both the quality of recovered silver and the integrity of the base material.

The system provides a high recovery rate, minimizing silver losses and delivering maximum economic benefits to the user. The efficiency of the machine allows companies to cut operational costs while increasing productivity.

Environmentally Friendly Process

Unlike traditional chemical stripping methods that can generate hazardous waste, this machine operates using a controlled electrolytic process. This approach not only reduces the consumption of harmful chemicals but also minimizes the discharge of toxic wastewater.

By incorporating advanced filtration and neutralization options, the machine ensures that the stripping process complies with modern environmental regulations. This makes it a sustainable choice for companies that aim to align their production with green manufacturing practices.

Safe and User-Friendly Operation

The machine is designed with operator safety as a top priority. The use of durable, corrosion-resistant materials ensures a long lifespan even under continuous operation. Safety mechanisms such as overload protection, proper insulation, and easy-to-operate control panels reduce risks and make the equipment suitable for operators of different skill levels.

The stainless-steel baskets are designed for convenient loading and unloading of materials, while the integrated design of the tank body ensures durability and stability during high-volume operations.

High-Quality Stripping Results

One of the most notable advantages of this equipment is the clean and precise stripping effect. It ensures complete removal of silver layers without damaging the underlying materials, making it particularly suitable for industries where the base material needs to be preserved for reuse.

The recovered silver is of high purity, ready for refining or direct reuse in production. This adds significant value for companies working in recycling or jewelry manufacturing, where maintaining metal quality is critical.

Customization and Flexibility

Each business has unique needs, and the Large-Scale Silver Stripping Machine can be customized to meet specific operational requirements. Options for tank size, basket capacity, and voltage configurations are available to suit different production environments.

In addition, optional accessories such as filtration systems, heating units, and automated handling equipment can be integrated for greater efficiency. This flexibility makes it a suitable solution for both medium-sized workshops and large-scale industrial plants.

Cost-Effective Investment

Investing in this machine means reducing manual labor, cutting chemical costs, and increasing metal recovery rates. Over time, businesses benefit from lower operational expenses, higher returns on silver recovery, and improved sustainability credentials. The machine provides a fast return on investment, especially for companies dealing with large volumes of silver-plated materials.

After-Sales Support

We provide comprehensive after-sales services, including installation guidance, training for operators, and long-term technical support. Spare parts and maintenance services are readily available, ensuring that your equipment remains in peak operating condition.

With reliable global logistics, the machine can be shipped to clients worldwide within a reasonable lead time. Our professional team is always ready to provide assistance, ensuring smooth integration into your existing production process.

Conclusion

The Large-Scale Silver Stripping Machine combines efficiency, safety, and environmental responsibility in one advanced solution. Whether you are in the jewelry, electronics, plating, or recycling industry, this machine offers a reliable method to recover silver while maintaining high standards of performance and sustainability.

It is more than just a stripping machine—it is an investment in efficiency, profitability, and a greener future for your business.