Description

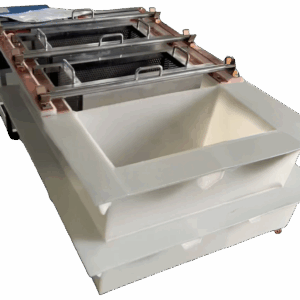

High Quality Gold Resin Recovery Machine Gold Adsorption Recovery Barrel for Gold Plating Solution

Gold Resin adsorption recovery machine is an efficient and environmentally friendly precious metal recovery technology, especially in the treatment of low-grade gold solutions (such as cyanide leaching solution, electronic waste leaching solution, electroplating wastewater, etc.). Its core is to use the selective adsorption ability of functionalized resins on gold ions (or gold-cyanide complexes).

1. Working Principle

The core technology of this machine is based on the selective adsorption ability of functionalized ion-exchange resins toward gold ions or gold–cyanide complexes.

In a gold-bearing solution, gold typically exists in the form of complex ions, such as [Au(CN)₂]⁻. The resin used in the system contains specific active functional groups—usually quaternary ammonium or other cationic groups—that can exchange with the anions in these complexes. During operation, the resin selectively attracts and binds gold ions, allowing them to accumulate on the resin surface while other impurities remain in the solution.

This ion exchange process enables efficient separation, enrichment, and recovery of gold, even from solutions with extremely low concentrations of precious metals. Compared with traditional precipitation or electrolysis methods, resin adsorption is cleaner, faster, and more stable, with minimal energy consumption.

2. Structure and Composition of the Resin

The gold-absorbing resin is typically synthesized from styrene-divinylbenzene copolymers, which form a robust three-dimensional cross-linked structure. This polymer skeleton provides excellent mechanical strength, chemical stability, and resistance to swelling or dissolution in complex solution environments.

The surface of the resin is further functionalized with specific strong or weak alkaline groups, which interact with gold ions or gold-cyanide complexes through chemical affinity. These groups determine the adsorption capacity, selectivity, and regeneration efficiency of the resin.

Moreover, the resin possesses a well-designed pore structure with a large specific surface area. These micro- and mesoporous channels create ample space for solution flow and allow gold ions to easily diffuse into the resin interior. The pores also ensure rapid adsorption kinetics, resulting in high recovery efficiency and fast reaction speed.

3. Equipment Features

-

High Recovery Rate:

The adsorption system achieves gold recovery rates above 98% for most plating or leaching solutions, ensuring maximum utilization of gold resources. -

Environmentally Friendly Process:

No cyanide decomposition or secondary pollution occurs during adsorption. The process water can often be reused after treatment, significantly reducing environmental impact. -

Automatic Control and Continuous Operation:

The machine is equipped with an automatic circulation system that continuously pumps solution through the resin bed, allowing 24-hour stable operation with minimal human supervision. -

Regeneration and Reusability:

After gold saturation, the resin can be regenerated using mild elution agents, allowing repeated use without loss of performance. This greatly reduces operational costs. -

Compact and Durable Design:

The adsorption barrel and pipelines are made of acid- and alkali-resistant materials, such as PVC, PP, or stainless steel, ensuring long-term stability in harsh environments.

4. Gold Elution and Recovery Process

Once the resin reaches its gold adsorption capacity, it undergoes an elution process to release the captured gold.

In most systems, a special thiourea or sodium sulfite solution is used as the desorbing agent. These agents selectively strip the gold from the resin surface without damaging its active groups. The desorbed gold solution is then concentrated and can be subjected to electrolytic refining, precipitation, or reduction to obtain pure metallic gold.

This closed-loop process achieves zero liquid waste discharge, making it highly compliant with environmental regulations and industrial sustainability standards.

5. Applications

The Gold Resin Recovery Machine is widely used in:

-

Gold plating workshops and jewelry manufacturing plants

-

Electronic component and semiconductor industries

-

Gold mining and metallurgical research labs

-

Recycling facilities handling waste electroplating or leaching solutions

-

Universities and R&D institutes conducting precious metal recovery experiments

It can handle cyanide-based, thiosulfate, chloride, and mixed complex gold solutions, showing strong adaptability to different production conditions.

6. Advantages Over Traditional Methods

Compared with conventional gold recovery methods—such as activated carbon adsorption, chemical precipitation, or electrowinning—the resin adsorption method offers several notable advantages:

-

Higher Selectivity: The resin specifically targets gold ions while ignoring other metals like copper or nickel.

-

Lower Energy Consumption: No need for high-temperature heating or strong electrical current.

-

Simplified Operation: The system can operate continuously with minimal maintenance.

-

Reduced Chemical Use: The process requires fewer toxic chemicals and produces little hazardous waste.

-

Scalable Design: Equipment can be customized from laboratory scale to industrial-scale production lines.

7. Material and Structural Safety

The adsorption tanks are constructed from high-strength polypropylene (PP) or stainless steel (SS316), ensuring durability under corrosive conditions.

All connecting pipes and valves are resistant to acid, alkali, and chlorine corrosion, making the equipment suitable for a wide range of chemical environments. The modular design allows easy installation, cleaning, and maintenance.

8. Technical Parameters (Example)

| Parameter | Description |

|---|---|

| Model | GRM-50 / GRM-100 / GRM-300 |

| Resin Type | Strong Base Anion Exchange Resin |

| Flow Rate | 50–500 L/h |

| Gold Recovery Rate | ≥98% |

| pH Range | 2–12 |

| Operating Temperature | 10–60°C |

| Material | PP / Stainless Steel |

| Control System | PLC Automatic Circulation |

| Elution Agent | Thiourea or Sodium Sulfite Solution |

9. Conclusion

The Gold Resin Adsorption Recovery Machine is a cutting-edge, environmentally sustainable solution for precious metal recovery in modern industries.

By leveraging the powerful adsorption properties of specialized resins, it efficiently extracts and recovers gold from a wide range of low-concentration solutions.

Its combination of high recovery rate, strong chemical resistance, easy operation, and reusability makes it an ideal choice for gold recovery plants, jewelry manufacturers, and research institutions seeking to reduce waste and maximize metal yield.

In a time when global environmental standards and gold prices continue to rise, adopting this advanced gold recovery technology represents not only a smart economic investment, but also a responsible commitment to green production and resource recycling.