Description

| Warranty | Key Selling Points | Machine Type | Place of Origin | After-sales Service Provided | Function | Capacity | Payment Method | Machinery Test Report | Video Outgoing-inspection | Core Components | Brand Name | Principle | Weight | Size | Trade Terms | Power Supply | Packaging Details | Port of Dispatch | Selling Units | Supply Ability |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

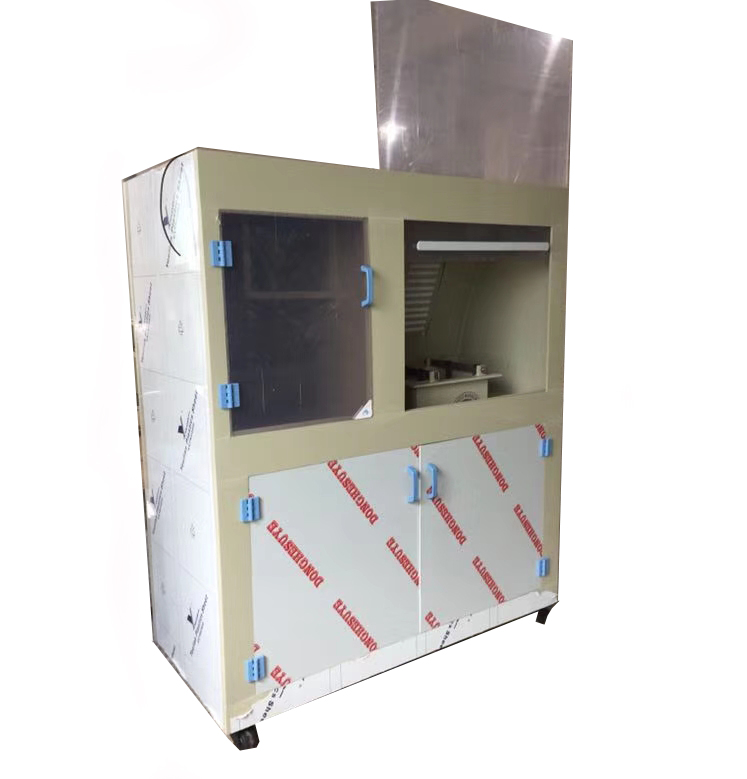

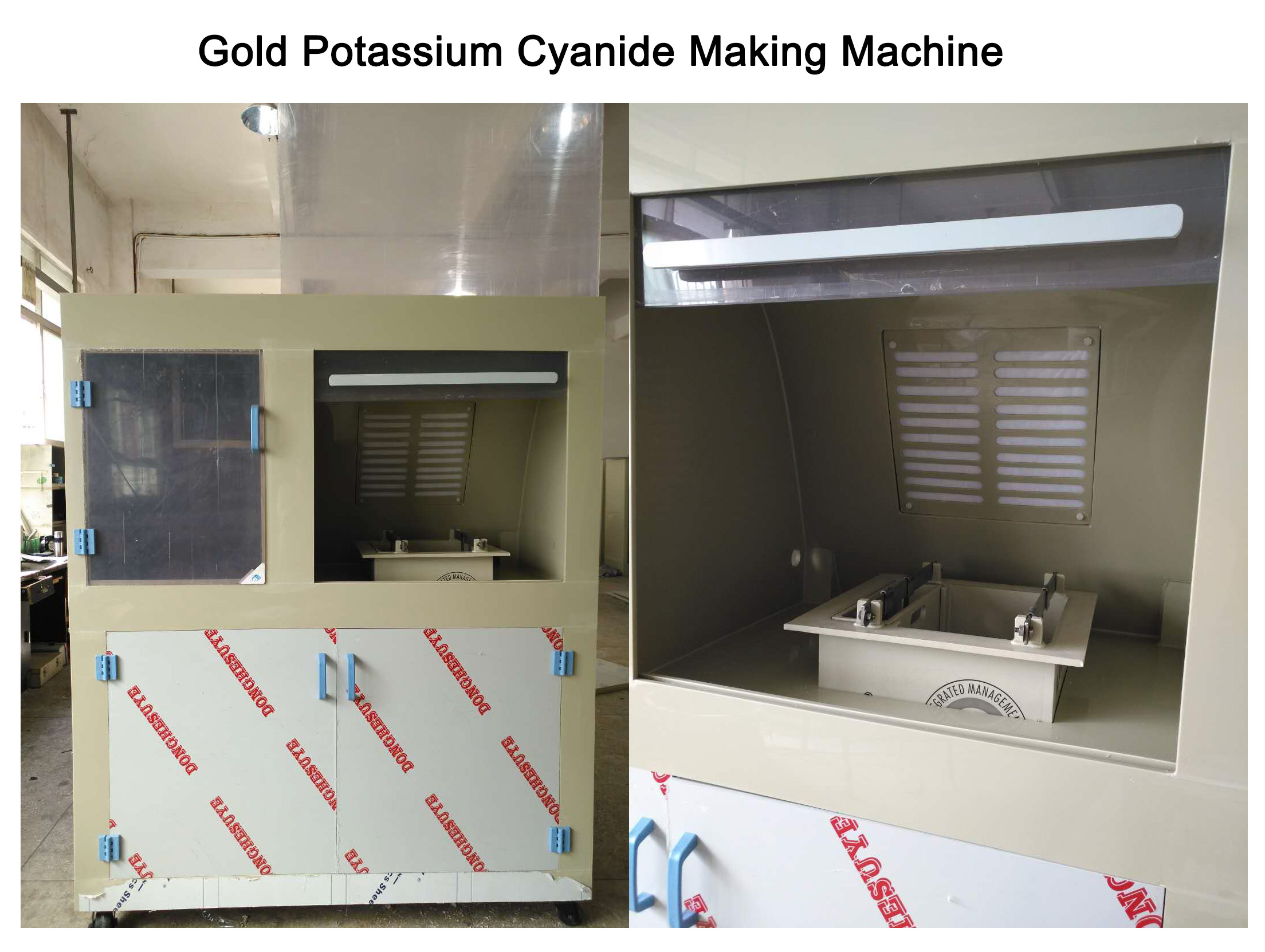

| 1 Year | Easy to Operate | Gold Electrolytic Machine | Guangdong, China | No overseas service provided | Produnction of the pruity of 68.3% gold cyanide potassium | 2KG/5KG | L/C,T/T,Western Union.etc | Not Available | Provided | Rectifier,Filter Membrane | XHF | Diaphragm Electrolysis | 130KG | 1320*750*1830mm | EXW,FOB,FCA,CFR,CIF,DDU | 220VAC 60HZ/AC 380V 50HZ | Wooden Case Packing | Shenzhen | Single Item | 300 Sets Per Year |

Function:it is use to make the gold potassium cyanide with purity of 68.3%. the gold potassium cyanide is the raw materials of electroforming and electroplating.

Material: PP plate

Principle:Production of gold salt (gold potassium cyanide ) by diaphragm electrolysis

Main Material:Gold Potassium cyanide Potassium hydroxide.

Capacity:1kg/batch 2kg/batch 5kg/batch (also can according to customer’s needs to customized.)

Advantages of gold salt machine:

Advanced technology: The use of advanced electrolysis to produce gold salt, and the addition of polymer filter membrane separation technology on the basis of electrolysis, fully guarantees the purity of the produced gold salt.

The electrolytic tank is welded firmly and strictly leak-proof: Our company fully considers the preciousness of the liquid in the gold salt electrolytic tank, and strictly controls the welding quality during the production process to ensure that the electrolytic tank does not leak water and will not cause gold loss. After welding, test the electrolytic tank for leaks with water several times. Make sure that the electrolytic tank is completely water-proof, and it is considered qualified.

Gold loss is minimized: on the one hand, the electrolysis method produces gold salt, which reduces the loss of gold. On the other hand, a filter cotton is installed at the exhaust gas suction port to filter and recover a small amount of gold in the exhaust gas. Minimize gold loss from these two aspects.

Equipment configuration

(1) Rectifier (electroforming power) (2)Titanium anode and cathode

(3) Filter membrane (4)Heating and temperature control device

(5) Time control device (6) Exhaust gas collection system

| Machine Name | Quantity | Dimension | Function |

|

Gold potassium cyanide

making machine

|

1 set

|

1500*750*1830mm

|

The machine is used for producing

gold potassium cyanide

|

|

Toxic gas treatment

machine

|

1 set

|

diameter1000*2400mm

|

The machine is used for treating

toxic gas that generated from gold

potassium cyanide making

machine.

|

|

Gold Tablet press machine

|

1 set

|

Self-purchasing/

Or buy from us

|

The role of the tablet press is to

process the gold nuggets into thin

gold pieces.

|

|

Refrigerator

|

1 set

|

Self-purchasing

Or buy from us |

The function of the refrigerator is

to obtain gold salt by cooling and

crystallization.

|

|

Oven

|

1 set | Self-purchasing

Or buy from us |

The role of the oven is to dry gold salt. |

|

RO water making

machine

|

1 set | Self-purchasing

Or buy from us |

Production RO water for making GPC |

Packaging: carton + wooden box

Shipping Ways:

Door to Door service by Express (DHL, Fedex, UPS, TNT, EMS ,etc)

From airport to airport by Air

From sea port to sea port by Sea