Description

| Warranty | Place of Origin | Keyword | Application | Raw Material | Machine Type | Brand Name | After-sales Service Provided | Usage | Packaging Details | Port of Dispatch | Selling Units | Supply Ability |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 Year | Guangdong, China | Refining Machine | For Refining and Melting Gold | Pure Titanium | Gold Refining Machine | XHF | Engineers Available to Service Machinery Overseas | Gold Refining | Wooden Case Packing | Shenzhen | Single Item | 300Sets Per Month |

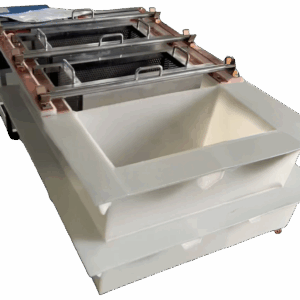

Factory price gold refining machine

Material: commercial pure titanium plate, with titanium purity of 99.9%.

Function: aqua regia is added to the reactor for gold melting and then cooling down, to obtain a solution containing gold.

Structure: reactor housing + water inlet + air inlet+ exhaust vent + electric heating and temperature control device.

Specification: 10-20KG gold / each time.

Advantages of titanium gold melting reactor:

1) Fast heating up and cooling down: This reactor is equipped with electric heating, the material temperature can be automatically controlled according to technological requirements.

2) Special structural design: This reactor has advanced structure and good sealing. During the process of gold melting, it can prevent corrosive acid gases releasing to the surroundings, endangering human health and polluting the environment;

3) Design of suction opening: unique suction opening design can quickly suck up exhaust concentrated acid mist generated during gold melting. (Exhaust concentrated acid mist that sucked away can be treated with our matching purifier. Efficiency of exhaust purification can reach to 99%.)

4) High temperature resistance: excellent heat resistance, wide operating temperature range (-25 ~ 600 ℃).

5) Strong corrosion resistance: Due to the characteristics of acid resistance, alkali resistance, high temperature resistance and chloride ions resistant, titanium materials can be applied to the purification of gold scrap and silver scrap with various properties, without causing corrosion to the equipment.

6) Excellent mechanical properties: Titanium materials have good process ability and mechanical properties, which can be produced to reactors with different shapes and configurations according to process requirements. It can withstand high working pressures. Reactor wall may be polished to prevent materials hanging, and facilitate cleaning.

Company provides design and manufacture of the entire system of gold refining. You’re welcomed to give us a call or visit us.

High-Performance Titanium Reactor for Gold and Silver Refining

Our titanium reactor is a specially designed industrial equipment used in the refining, purification, and recovery of precious metals such as gold and silver. It combines high efficiency, safety, and durability, offering a stable and environmentally friendly solution for metal refining industries. This reactor is particularly suitable for gold purification, gold stripping, and other chemical processes involving strong acids and high temperatures.

1. Fast Heating and Cooling Performance

This titanium reactor is equipped with a high-efficiency electric heating system that allows rapid heating and cooling. The temperature control system can automatically regulate the internal temperature according to specific process requirements, ensuring consistent performance throughout the refining process.

The precise temperature adjustment helps maintain stable chemical reactions, improving metal recovery efficiency while preventing over-heating or energy waste. Compared with traditional heating reactors, the response speed of this model is significantly faster — saving both time and electricity. This intelligent temperature control ensures that each batch of gold or silver is processed under the optimal conditions, maintaining high purity levels and minimizing losses.

2. Special Structural Design and Sealing Technology

The reactor adopts an advanced structural design with excellent tightness and corrosion resistance. During the gold or silver melting process, harmful and corrosive acid gases (such as nitric acid vapor and hydrochloric acid gas) are effectively sealed inside the reactor chamber.

This not only prevents toxic gases from escaping into the surrounding environment but also protects workers from harmful exposure and minimizes air pollution.

The superior sealing design extends the overall service life of the reactor and improves workplace safety. The body of the reactor is made of high-grade titanium material, with welding seams reinforced to ensure long-term stability even under high temperature and high-pressure conditions.

3. Unique Suction Opening Design

A specially engineered suction opening is integrated into the reactor to deal with acid mist and exhaust gas generated during gold refining or melting.

When the metal is processed, a concentrated acid mist may form due to the high-temperature chemical reaction. The suction port immediately captures and extracts this exhaust, preventing it from spreading into the workspace.

The captured gas can then be connected to our matching purification unit, which filters and neutralizes harmful components. The exhaust purification efficiency can reach up to 99%, ensuring the gas emission meets international environmental standards.

This thoughtful design not only enhances operator safety but also significantly reduces environmental impact, making this reactor ideal for facilities that prioritize green and sustainable production.

4. Excellent High Temperature Resistance

Titanium material provides the reactor with outstanding thermal stability. The equipment can operate safely across a wide temperature range from -25°C to 600°C.

Even when exposed to extremely high temperatures for long periods, the reactor maintains its mechanical strength, dimensional stability, and surface integrity.

Unlike stainless steel or glass-lined reactors, the titanium reactor does not deform, crack, or suffer from coating detachment at elevated temperatures. This makes it ideal for intensive gold refining applications, where temperature fluctuations are frequent and rapid.

The excellent thermal conductivity of titanium also contributes to even heating of the entire reactor body, preventing hot spots and ensuring uniform chemical reaction results.

5. Superior Corrosion Resistance

One of the most outstanding properties of titanium is its exceptional corrosion resistance. This reactor can withstand prolonged exposure to strong acids, alkalis, and chloride ions without degradation.

During the refining of gold and silver, various chemical solutions such as aqua regia, nitric acid, hydrochloric acid, and sulfuric acid are often used. Ordinary steel or glass reactors may corrode or erode over time, leading to leaks and contamination.

Titanium, however, forms a stable oxide film on its surface, which protects it from chemical attack. This allows it to handle even the most aggressive refining solutions while maintaining structural integrity.

Because of this property, the reactor can be used for purifying gold scrap, silver scrap, and mixed precious metal residues, all without damaging the equipment. It is a long-term investment for refineries seeking durability and consistent performance.

6. Excellent Mechanical and Processing Properties

Titanium not only resists corrosion but also offers superior mechanical strength and workability. It can be shaped, welded, and processed into reactors of various sizes and configurations according to specific process needs.

This means the reactor can be fully customized — from volume capacity and wall thickness to inlet/outlet configuration and heating mode — to match different industrial production lines.

The material’s high tensile strength enables it to withstand elevated pressures during operation, maintaining structural safety even under harsh working environments.

Furthermore, the reactor’s inner wall can be polished to prevent materials from sticking, improve chemical flow, and simplify cleaning after each cycle. This smooth internal surface design also helps maintain the purity of the refined metals by avoiding contamination from residual materials.

7. Energy Efficiency and Environmental Protection

In addition to mechanical excellence, this reactor contributes to energy-saving and environmental protection. The electric heating system offers high conversion efficiency, reducing electricity consumption compared to conventional thermal oil or steam heating methods.

Combined with its gas-tight sealing and efficient exhaust purification design, the reactor ensures minimal environmental emissions and complies with global environmental regulations.

For companies pursuing ISO environmental certification or green manufacturing standards, this titanium reactor is an ideal solution that reflects both technological innovation and eco-responsibility.

8. Applications and Industries

This titanium reactor is suitable for a wide range of precious metal refining and plating applications, including:

-

Gold refining and purification

-

Silver electrolysis and recovery

-

Jewelry manufacturing and finishing

-

Laboratory and small-scale metal recovery research

-

Precious metal chemical synthesis

Its strong adaptability allows it to work seamlessly in acidic, alkaline, and high-temperature environments, making it one of the most versatile pieces of equipment in the precious metal processing field.

9. Summary

In summary, the Titanium Reactor for Gold and Silver Refining combines cutting-edge engineering, intelligent temperature control, superior corrosion resistance, and environmental protection in one integrated system.

Its high efficiency, stable performance, and customizable design make it a preferred choice for professional refiners, jewelry manufacturers, and chemical laboratories worldwide.

Whether used for gold melting, purification, or acid treatment, this reactor delivers reliable operation, long service life, and excellent safety performance — helping your business achieve higher productivity and cleaner production.