Description

| Warranty | Weight(KG) | Brand Name | Available Material | Power | Filtration Capacity | Filtration Area | MOQ | Condition | Place of Origin | Product Name | Temperature | Applicable for Plating Bath | Filter Element Qty | Outlet&Inlet Diameter | Packaging Details | Port of Dispatch | Selling Units | Supply Ability |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 Year | 37 | XHF | PP,PVDF,Acrylic | 150W | 80L/min | 1 cbm | 1 Set | New | Guangdong, China | Industrial Filter Chemical Water Filtration System | 70℃ | 800 Ton | 20‘’*4PC | 1‘’ | Packing Details Industrial Filter for Plating | Yantian, Shekou, Guangzhou, Shanghai | Single Item | 1000 Sets Per Month Chemical Water Filtration System |

Chemical Industry Filter | Industrial Chemical Water Filtration System

Product Description

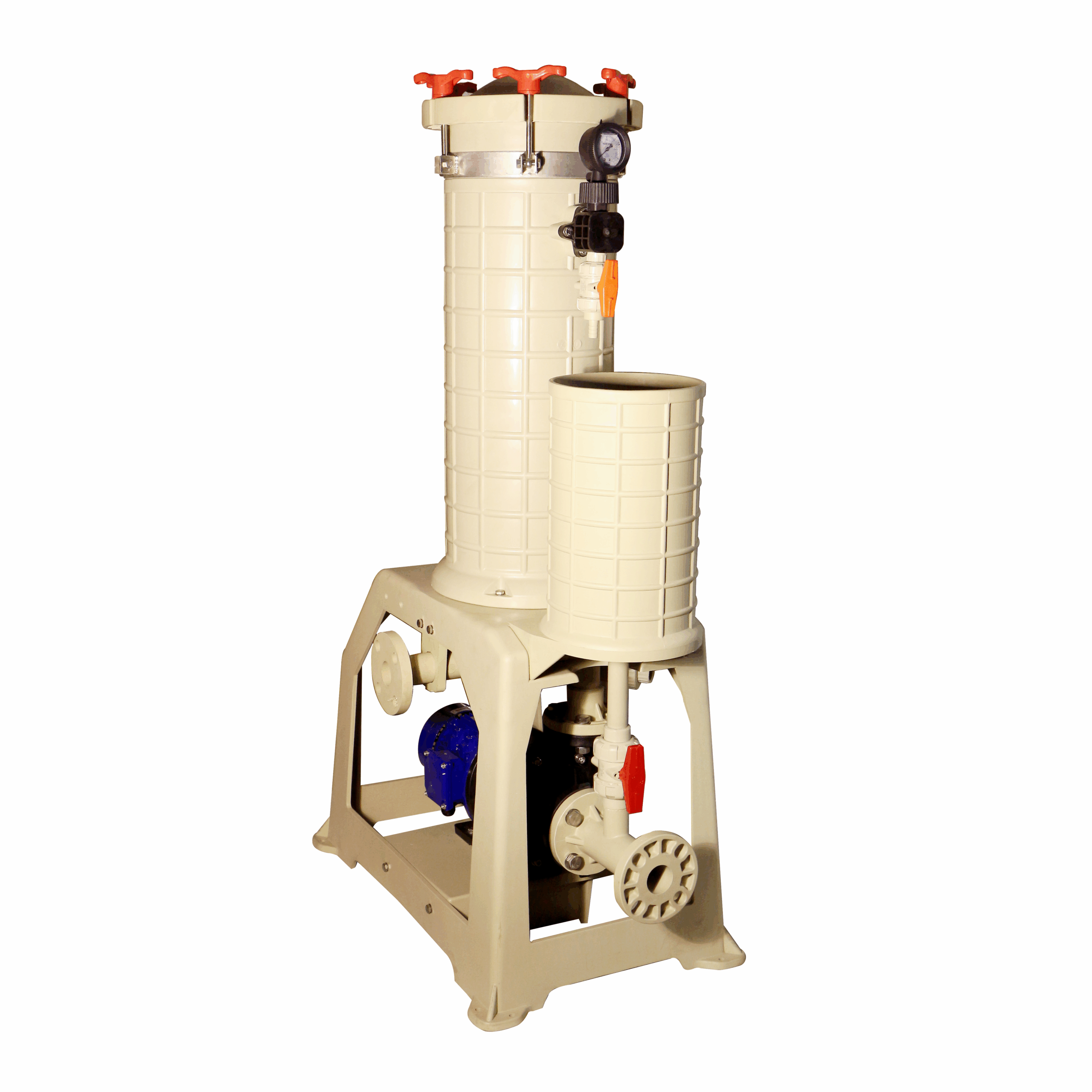

The Chemical Industry Filter is a highly reliable and durable filtration solution designed for industrial applications in electroplating, chemical processing, wastewater treatment, and pure water systems. Manufactured with high-quality PP (polypropylene) injection moulding, this filter ensures resistance to acids, alkalis, and elevated temperatures, making it suitable for harsh working environments. Its advanced design allows continuous and precise purification of chemical liquids, improving overall production efficiency, reducing impurities, and ensuring stable product quality.

This industrial filter is widely adopted in the fields of electroplating and electroforming, where solution cleanliness directly affects plating thickness, brightness, adhesion, and overall product performance. With its modular structure and easy-to-maintain design, the Chemical Industry Filter provides industries with a long-term, cost-effective, and environmentally friendly filtration solution.

Features

-

Wide Application in Liquid Circulation

Specially designed for the circulating filtration of electroplating and electroforming solutions, chemical liquids, and pure water, ensuring constant high-purity results. -

Zero-Leakage Pump Design

The glandless pump structure guarantees absolute zero leakage, ensuring both operational safety and stable liquid transfer during filtration. -

High-Precision Filtration

Equipped with a filter element design that allows wide filtration area coverage, high efficiency, and improved liquid clarity. This enables the filter to effectively remove fine particles, sludge, and impurities. -

Durable Material Structure

The filter body is manufactured from PP plastic steel, with optional PP or transparent acrylic construction to meet specific industry needs. -

Temperature Resistance

The transparent acrylic version is suitable for solutions with temperatures up to 60℃, while PP offers superior performance under both high-temperature and chemically aggressive environments. -

Acid and Alkali Resistance

PP injection moulding construction provides excellent resistance to strong acids and bases, making it ideal for chemical industries. -

Activated Carbon Filtration Option

Activated carbon grains can be placed inside the filter bag for additional purification. The processed liquid then passes through the filter element for secondary filtration, resulting in cleaner, purer chemical solutions. -

User-Friendly Design

Easy to assemble, operate, and clean, ensuring reduced downtime and lower maintenance costs.

Applications

-

Electroplating Industry – Removal of impurities from plating solutions to ensure high-quality plating results.

-

Electroforming Processes – Maintaining purity in precious metal solutions for fine and detailed electroforming.

-

Chemical Industry – Filtration of aggressive chemical liquids such as acids, alkalis, and organic solvents.

-

Water Treatment Systems – Used in pure water preparation and industrial wastewater recycling.

-

Pharmaceuticals – Ensures precise filtration of sensitive chemical liquids for laboratory and production use.

-

Electronics & Semiconductor Industry – Provides ultra-clean filtration for sensitive production processes.

Advantages

-

Stable Performance: Consistent filtration results improve overall production efficiency.

-

Customizable Options: Available in PP or acrylic construction, with different cartridge sizes to suit customer needs.

-

Eco-Friendly Operation: Reduces chemical waste and contributes to sustainable manufacturing.

-

Cost-Effective Maintenance: Easy replacement of filter cartridges lowers operational costs.

-

Enhanced Safety: Leak-free pump and corrosion-resistant material ensure safe long-term operation.

Technical Notes

-

Material Options: PP plastic steel, PP injection moulding, transparent acrylic.

-

Temperature Range: Acrylic filter body ≤ 60℃; PP filter body resistant to higher temperatures.

-

Filter Cartridge: High precision, large filtration surface, long service life.

-

Additional Purification: Activated carbon bag available for enhanced liquid medicine purification.

-

Pump: Glandless type, zero leakage, stable flow.

SEO Keywords

Chemical Industry Filter, Industrial Filter, Chemical Water Filtration, Chemical Filtration System, Electroplating Filter, PP Chemical Filter, Acid Resistant Filter, Alkali Resistant Filter, Activated Carbon Filtration, Industrial Water Treatment Filter, Electroforming Solution Filter, High Precision Filtration System, Chemical Liquid Purification