Description

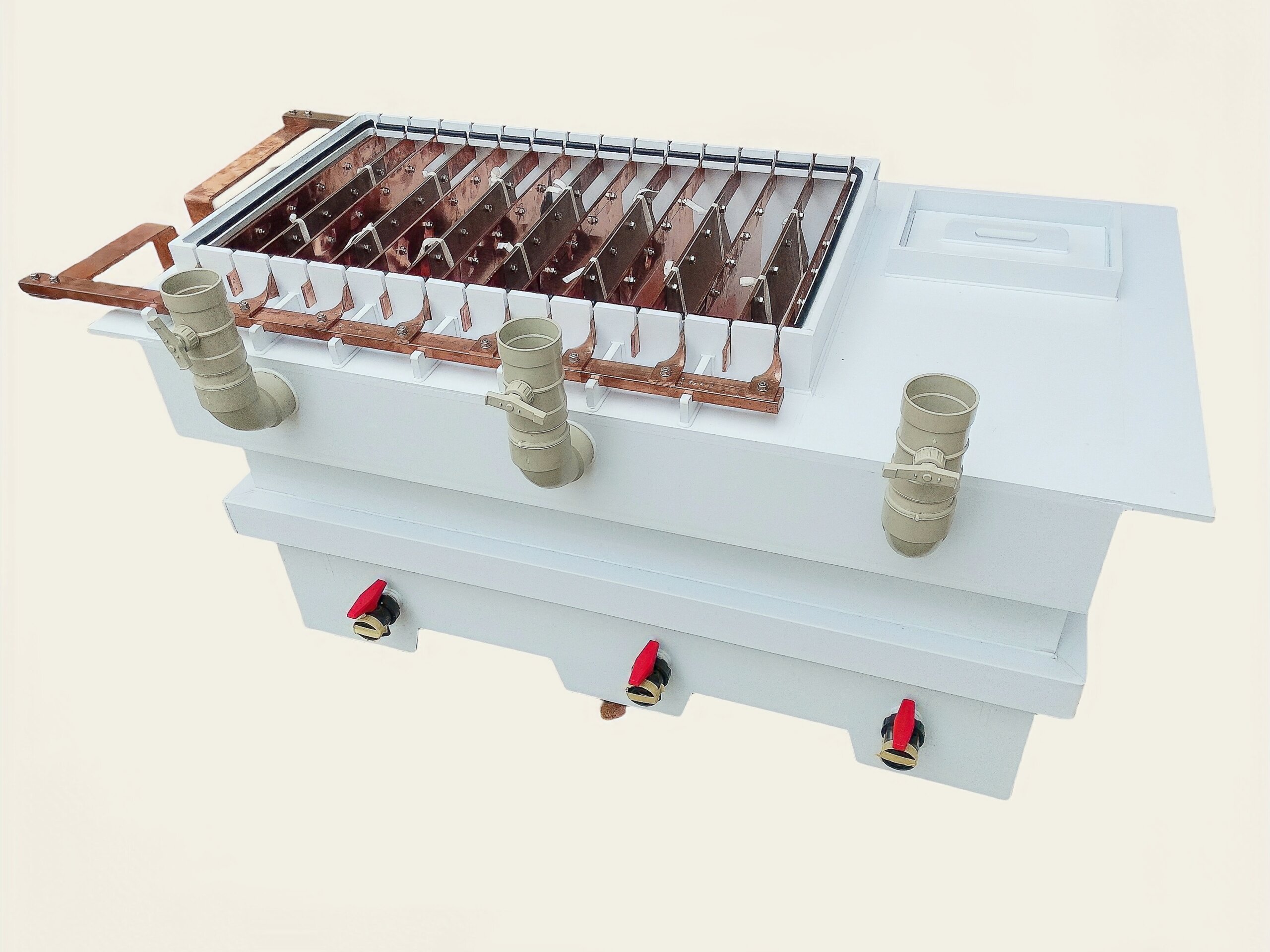

Automatic Scrap Copper Electrolysis Refining Machine Copper Cathode Making Machine

Capacity: 3-4kg/24H / Or can be customized

Function: The principle of electrolysis is used to refining 80% pure copper to 95%~99.99% copper.

| Warranty | Machinery Test Report | Key Selling Points | Video Outgoing-inspection | Machine Type | Core Components | Voltage | Power(KW) | Weight(KG) | Place of Origin | Brand Name | After-sales Service Provided | Function | Application | Capacity | Material | Feature |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 Year | Not Available | New Technology | Provided | Copper Electrolytic Refining Machine | PLC, Motor, Pump | 380V | 15 | 500 | Guangdong,China | XHF | Online Service Support | Refining Copper with a Purity of 80% to 99.99% | Refining Scrap Copper to High Purity Copper | 3kg/DAY | PP+Titanium Basket+Copper Sheet | High Purification Efficiency |

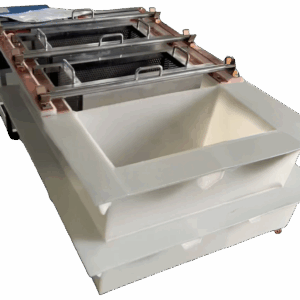

Size: Customized according to drawings

Composition: Copper content of more than 80%, as little as possible containing miscellaneous metals that affect the service life of the solution

Operational costs

1. Electricity cost: The copper content of the electrolyte is controlled at 10-20 grams per liter. The electricity cost budget is 3000-3500 degrees per ton of copper. The lower the copper content, the greater the average electricity consumption per ton of copper.

2. Reagent cost, the replacement cycle is determined according to the degree of contamination of the electrolyte by the composition of the crude copper.

Cathode copper purity

Depends on the cleanliness of the electrolyte.

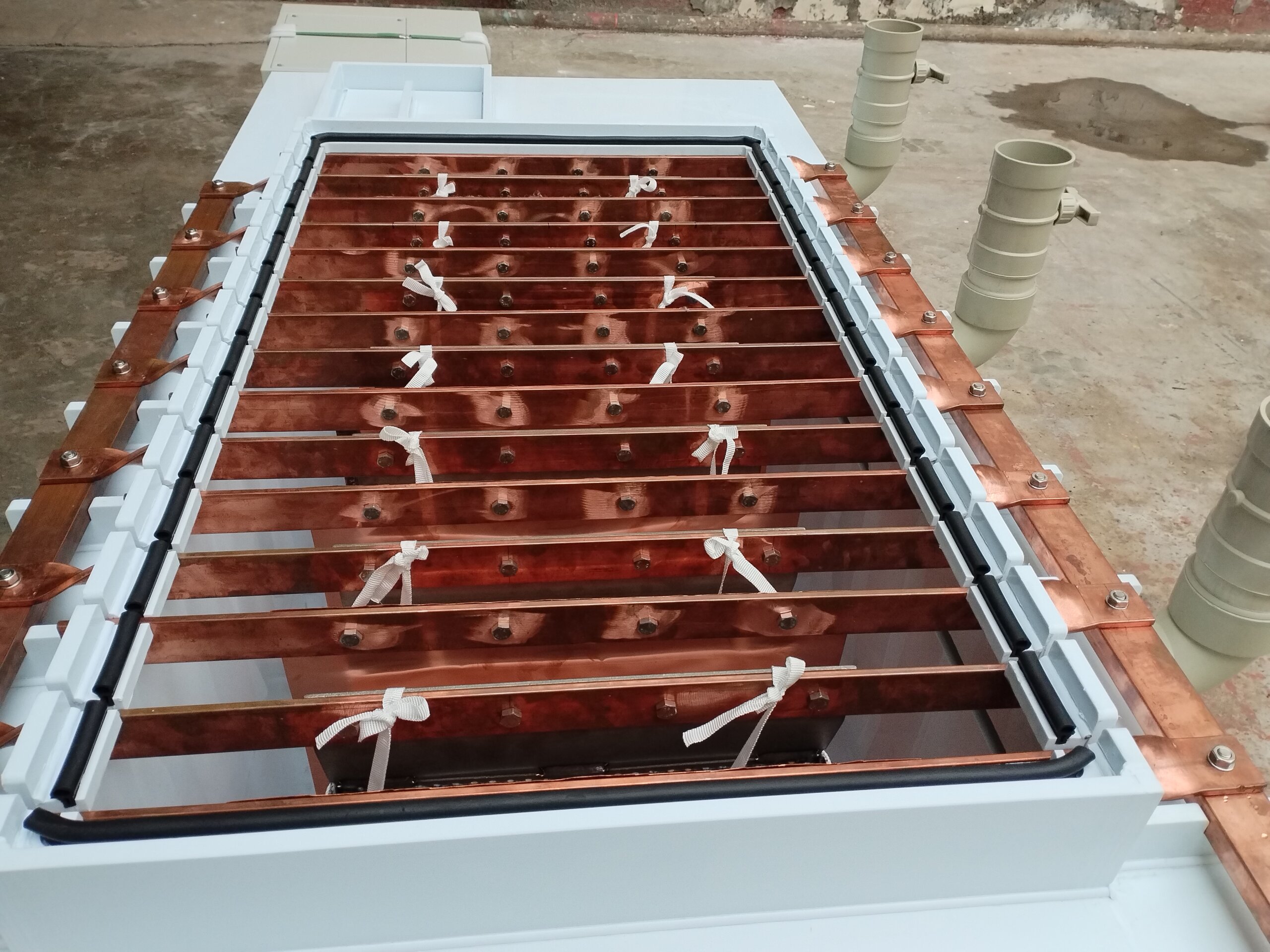

Working Principle

Using impure 80% copper as the anode and titanium plate (titanium basket) as the cathode, the anode is dissolved in the electrolyte, by using the principle of electrolysis, the dissolved copper will deposited on the cathode to form metallic copper again, finally to get the 95% ~ 99.9% purity copper.

Technical parameters

| Dimension | 1300*800*850mm |

| Material | PP |

| Power: | 380V/50HZ |

| Rectifier | 1000A/12V |

| Capacity: | 3-4kg/day (Capacity can be customized) |

| Electrolytic solution | Copper sulfate solution |

| Cathode | Cathode sheet with scraper |

| Anode | impure 80% copper with titanium basket |

| Pump | Acid and alkali corrosion resistant circulation pump |

The number of times to change the electrolytic solution: it is based on the purity of the unrefined copper block content. For example, the copper sulfate solution with low copper content and high impurity content has a poor cleanliness, and the solution needs to be replaced once for each Refining. For example, if the copper content is high and the copper block with few impurities , the potion can be reused several times, and the number of changes depends on the cleanness of the copper sulfate solution.

The advantage of the machine

1. This machine adopts advanced intelligent electrolysis technology and only consumes a small amount of electricity (15KW) to achieve efficient refining of precious metals. The application of this technology not only improves refining efficiency, but also reduces the impact on the environment.

2.The machine can quickly electrolyze and refine copper to a high purity of 99.9%.

3.The machine is designed with full consideration of the use environment, and the fully anti-corrosion design ensures long life of the parts and stable operation of the machine.In addition to being resistant to acids, alkalis, and corrosion, this equipment provides excellent protection for operators. Its fully automated operation shields operators from the harmful effects of corrosive acid and alkali solutions.

4.The machine have been produced in series with complete specifications, and can also be customized according to customer needs. With its technological innovation and excellent performance, this machine has significant advantages in the field of precious metal refining. It provides enterprises with efficient, environmentally friendly and economical solutions, helping to promote the sustainable development of the industry.