Description

| Video Outgoing-inspection | Warranty | Purify Efficiency | Place of Origin | Keywords | Feature | Function | Composition | Machinery Test Report | Core Components | Weight(KG) | Brand Name | Application | Certificate | After-sales Service Provided | Packaging Details | Port of Dispatch | Selling Units | Supply Ability |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Provided | 1 Year | More Than 98% | Guangdong, China | Gold Jewelry Acid Bombing Machine | Safety/Easy Operation/Environmental Friendly | Industrial Waste Gas Purification | Acid Gas Purification System+PH Control Device+Fan+Water Pump | Provided | Pump,PLC,Furnace | 500KG | XHF | Cleaning Jewelry with Heated Acid | Inventional Patent Verification | Video Technical Supported | Export Cation+Wooden Box Packaging | Shenzhen Port | Single Item | 100 Sets Per Month |

Gold Jewelry Acid Bombing Cabinet / Gold Jewelry Acid Polishing Cabinet

Function: Heating sulfuric acid (H2SO4) and nitric acid (HNO3) with gold jewerly. one

function is remove the copper inside the jewelry, another function is make

the color of the jewelry more shining.

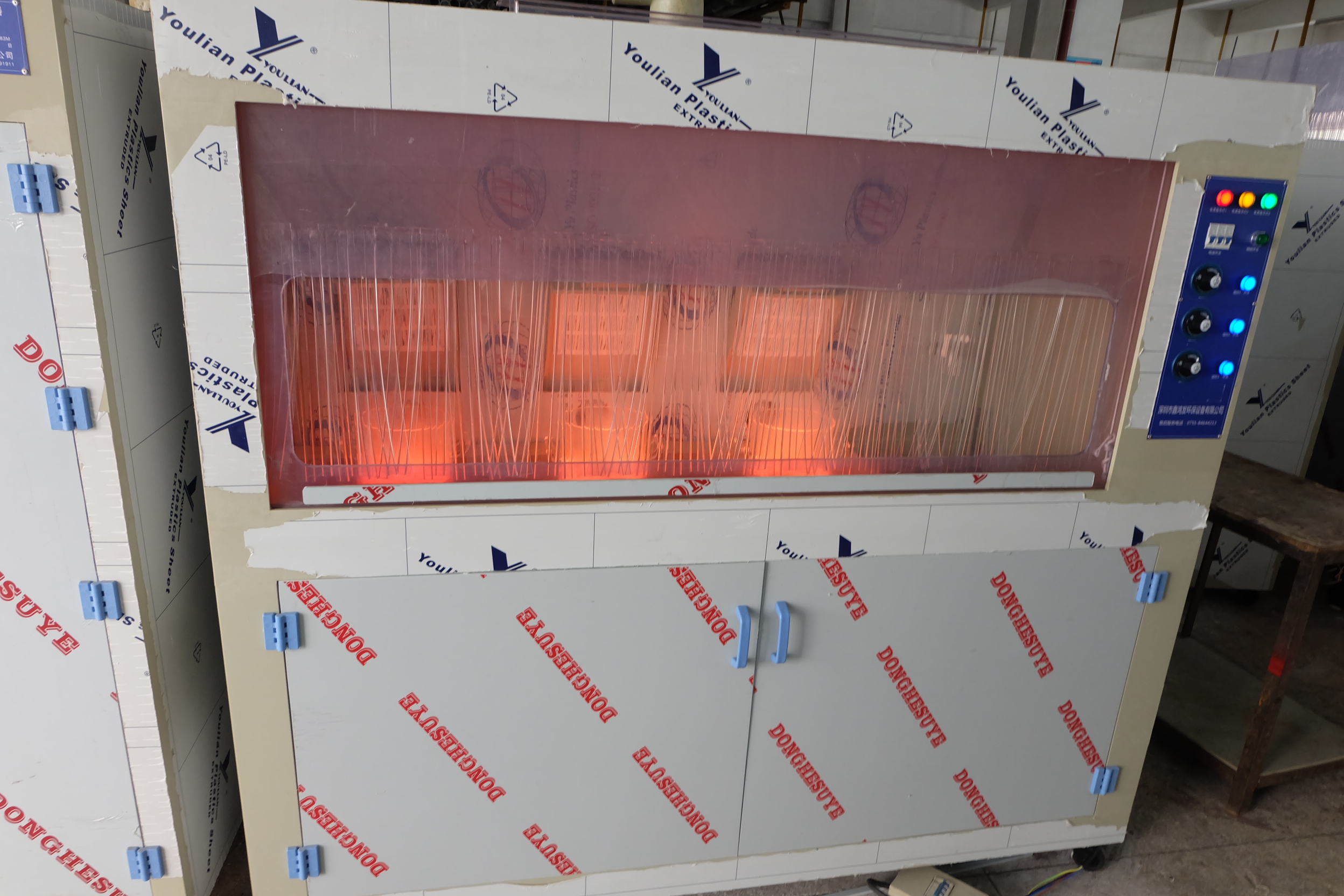

he Acid Burning and Color Hanging Cabinet is a professional piece of equipment specially designed for jewelry factories and electroplating workshops. It is primarily used for acid treatment, color hanging, and chemical cleaning of gold and silver jewelry, as well as other metal accessories. The cabinet is made of high-quality PP plastic with excellent acid and alkali resistance, high temperature resistance, and durability. Its design fully considers the safety, convenience, and environmental protection requirements of modern jewelry processing facilities.

1. Material and Structure

The cabinet body is constructed from industrial-grade PP (polypropylene) plastic, a material well-known for its outstanding chemical corrosion resistance and mechanical strength.

This allows the equipment to operate stably for long periods in harsh acidic environments without deformation, discoloration, or leakage. The smooth surface design also makes cleaning easy, ensuring the working area remains neat and safe.

All major components—including the working tank, exhaust system, and frame—are made of acid-proof materials, extending the service life of the equipment and preventing corrosion from strong acids such as nitric acid, hydrochloric acid, or aqua regia commonly used in jewelry processing.

2. Easy Operation and Control

The equipment is equipped with an electronic control system, making operation simple and efficient. Operators can control the heating, timing, and exhaust system through intuitive push buttons or a digital control panel.

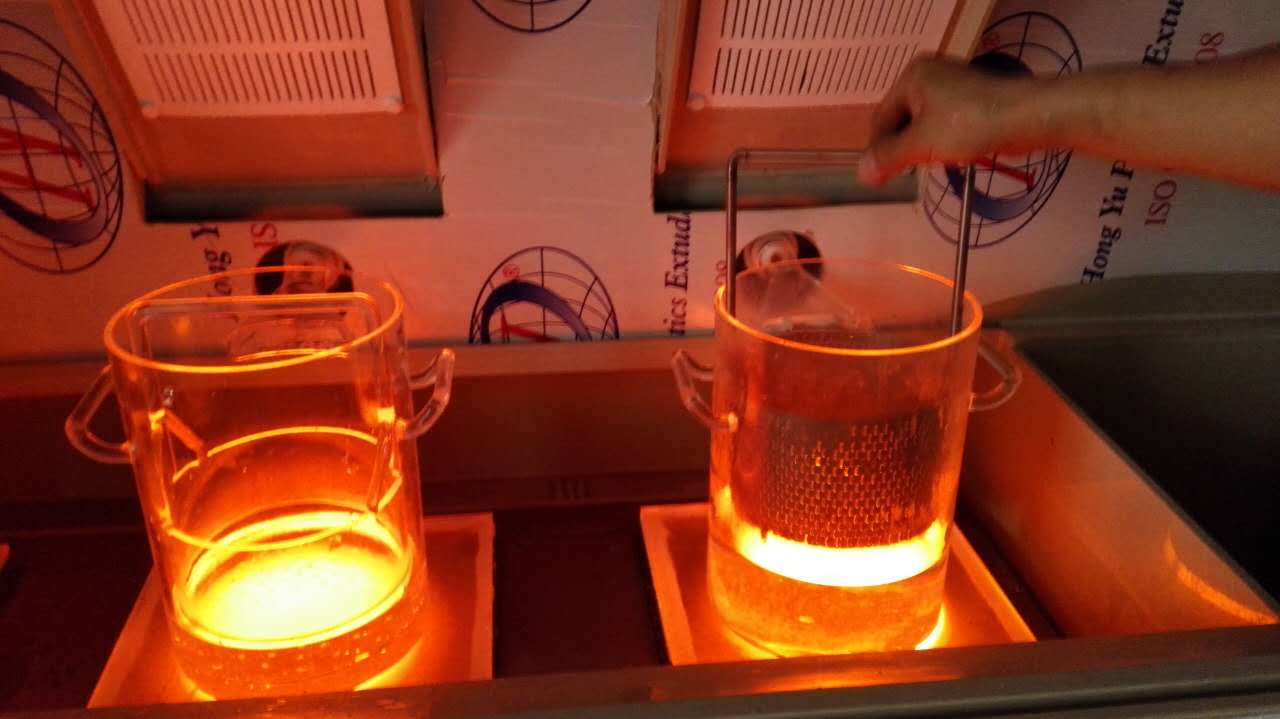

Quartz baskets are used to load and unload jewelry pieces. These baskets are fitted with heat-resistant handles, allowing safe movement during acid boiling or rinsing. The ergonomic design ensures both operating safety and production efficiency, even for new users.

3. High-Quality Quartz Beaker and Basket

Both the quartz beaker and quartz basket are made from imported German quartz material, which undergoes annealing at 1200℃ to achieve superior purity and strength.

These quartz components can resist high temperatures and maintain excellent stability under strong acid or alkali conditions. They are essential for handling gold and silver jewelry during acid boiling, color hanging, and cleaning processes.

Unlike ordinary glass containers, the quartz beaker does not release impurities into the solution, ensuring the color and surface quality of the jewelry remain consistent and flawless after treatment.

4. Infrared Electric Furnace

The internal heating system adopts an infrared electric furnace with all wires completely sealed and isolated from the corrosive environment. This design not only extends the service life of the heating elements but also ensures uniform temperature distribution during acid boiling or chemical reaction processes.

The heating is fast and energy-efficient, capable of quickly raising the temperature to the desired level while maintaining precise control to prevent overheating or acid splash.

5. Transparent Sliding Safety Door

A transparent sliding door is installed at the front of the cabinet. It serves a dual purpose:

-

Protecting operators from splashes of concentrated acid or hot liquid;

-

Allowing clear visual monitoring of the process without needing to open the cabinet.

This enhances both operational safety and working efficiency, ensuring that staff can observe the reaction in real time while remaining fully protected.

6. Efficient Exhaust and Smoke Management System

One of the key features of this equipment is its integrated thick smoke exhaust system.

An air exhaust port is installed at the top or rear of the cabinet to effectively capture acidic gas and vapor generated during acid burning or rinsing. The gases are directed to an external purification system or acid mist scrubber, ensuring that no harmful fumes escape into the workspace.

This design complies with modern environmental standards, preventing air pollution and safeguarding workers’ health.

7. Portable and Easy to Move

For easy installation and flexibility, the cabinet is equipped with durable industrial casters.

The smooth and stable wheels make it simple to move the entire cabinet around the workshop when needed—whether for maintenance, cleaning, or process adjustment. Once positioned, the cabinet can be locked securely to ensure safe operation.

Conclusion

The PP Acid Burning and Color Hanging Cabinet is a safe, efficient, and user-friendly solution for jewelry manufacturers and plating factories that perform acid treatment, color enhancement, or surface cleaning on precious metal products.

With its high-quality quartz components, infrared heating system, integrated exhaust design, and acid-resistant PP construction, this equipment guarantees long-term reliability, superior performance, and compliance with environmental and safety standards.

It is ideal for gold jewelry workshops, silver processing factories, and precious metal refining laboratories, where both product quality and operator safety are top priorities.

Multifunctional Strong Acid Gas Treatment Equipment

Features:

- 1) High purification efficiencyPurification efficiency: ≥98%. We can make sure the bad smell acid gas after treat by our machine, can realize colorless and odorless emission, and Exhaust gas at the outlet is in line with discharge requirements in GB16297-1996 “Air Pollutant Discharge Standard” and “Local Standard Atmospheric Emission Limits of Guangdong Province” DB44 / 27-2001.2) Easy to operate and more environmentally friendly

Easy to operate Simply control the buttons on the electronic control panel,then the machine will run normally. Environmentally friendly

When heating sulfuric acid (H2SO4) or nitric acid (HNO3) with gold jewelry , the strong acid gas can be collected and delivered immediately. Only need one consuming chemical Every day, depending on the actual use, only consume industrial alkali(NaOH). 2) Complete functional modules

NO Function modules Detailed description 1 Efficient neutralization purification system The acid gas is neutralized with a plurality of neutralization purification modules to neutralize the high concentration acid gas into neutral gas. 2

Automatic dosing device According to the frequency and usage of the machine, the machine will automatically detect and automatically add the chemical needed to meet the normal operation of the machine. 3

PH automatic detection device Automatic detection of the real-time pH of the neutralized lye in the device 4

High-voltage electrostatic smoke gas remover Purify white smoke in acid gas to achieve colorless and odorless emission after exhaust gas purification 5

Corrosion-resistant FRP centrifugal fan Transporting acid gas, and to provide the energy for acid gas to pass through the entire purification system